Grants

Landscape Regeneration

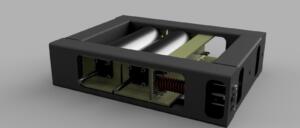

Flete Biochar Crusher

£5,000 awarded

Project Dates: 01.02.25 to 01.08.25

Flete Field Lab‘ s Biochar project turns waste wood from Flete Estate’s normal woodland management processes (such as trimming hedges and coppicing) into biochar that can be used as an alternative to synthetic fertiliser to enhance soil quality and reduce run-off and river pollution.

The project has so far processed 2,500kg of charcoal into biochar, which is the equivalent of 7,500kg of Co2 removed from the atmosphere, however there is scope for much more carbon to be sequestered if locally produced biochar could be produced and applied more efficiently.

Biochar has to be crushed to the right size to be incorporated properly to benefit the soil. There is an absence of appropriate mid-scale biochar crusher technology, with existing options being much larger (and more expensive) industrial-scale machines, so Flete Field Lab has designed an affordable biochar crusher to fill this UK gap.

DEF’s grant will support this new piece of equipment to be built and prototyped for use at the Flete Estate, South Devon to benefit neighbouring farmers, enabling them to add nutrients to their soil from local woodland waste. Once the design has been proven to work, it can be replicated to enable more farmers across Devon and the UK to benefit from using locally produced biochar.

Huge thanks to Olympus Power for generously donating to DEF to enable Flete Field Lab to develop this biochar crusher and increase the amount of carbon sequestered into local soil.

Image credits: Flete Field Lab

IMPACT SUMMARY December 2025

Project Activities:

Biochar Crusher development:

- The project has developed a biochar kiln which was design was developed in-house, fabricated locally, and tailored to small-scale production needs.

- The main structure is complete with the shafts and bearings are installed.

- The next steps are fitting the motor and drive system, followed by testing.

- The steel frame is extremely sturdy and great for long-term durability.

- One of the project’s volunteers, Tibor Kordic, has helped with the building of the machine and making some important improvements.

Alongside fabrication and assembly, the project team have kept producing charcoal. Since early summer they have made around 1,000 kg, bringing the total production to over 4,200 kg, (nearly 10 tonnes CO₂e) used in the soil field trials and water pollution trials, and have more field research ongoing, with more sites to apply biochar.

Additional positive impact: the new water-pollution trial results have shown to be very encouraging. Biochar used alongside mycofiltration is proving highly effective at removing pollutants (10 – 30%) from small waterways. This has huge potential for low-cost nature-based solutions in rural catchments. The crusher will help us scale that work too, by giving the project consistent, high-quality material.

Project Outcomes:

- The project has delivered a highly functional and long-lasting machine, and has created new opportunities for knowledge-sharing and replication with other biochar producers.

- A key achievement is solving a frustrating bottleneck in biochar production: breaking the produced charcoal into particle sizes appropriate for incorporation into the soil.

- The crusher design could be shared with other community biochar groups, or there is potential to produce pre-built crushers as a product for other biochar makers.

- Biochar is being proven to have a positive impact on pollution filtration.